Shenzhen Newei Industrial : Your Trustworthy Air Compressor Manufacturer!

Our company was established in 2014 and is deeply focused on the vehicle-related auto parts industry and smart wearable device industry. Our products are sold to more than 70 countries around the world and are highly satisfied and positively evaluated by customers at home and abroad. It is a comprehensive enterprise integrating design, research and development, manufacturing, sales and service.

Rich Products

Our company can produce high-quality air pumps, car portable tire pressure pumps, portable electric smart air pumps, air compressors, handheld automatic cordless tire inflators, tire inflators, LED digital display car electric pumps, emergency start air pumps, etc.

Quality Assurance

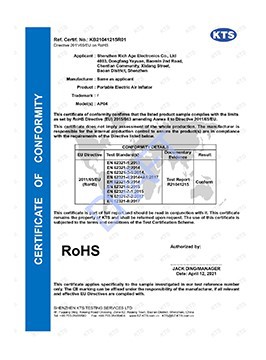

As an original manufacturer certified by BSCI and approved by the ISO9001:2015 international quality management system, all of our company's products have passed 3C\CE\FCC\ROHS certification and have a number of appearance and utility model patents and invention patents.

Customizable

We can provide you with one-stop ODM/OEM customization services from solution introduction, design, R&D, mold opening, and production.

Many Partners

We have senior industrial design and software and hardware design talents in the industry, own more than 20 national technology patents, more than 40 software copyrights, and maintain relationships with well-known auto parts companies such as Caterpillar, BMW, Mini, Disney and other internationally renowned brands. good cooperation.

-

LED Light Portable Electric Air Compressor

An electric car tire inflator is a device that uses electric power to fill a car's tires with air. Add to Inquiry -

portable intelligent air pump

A practical and convenient air pump is undoubtedly a necessary tool for travelling. Today, we would Add to Inquiry -

Travel Tyre Car And Bike Tyre Inflator

The AP04 Bike Tire Air Compressor Pump is an incredible investment for anyone looking for a smart Add to Inquiry -

Car Charger Tire Inflator

AP02 Car Charger Tire Inflator is designed to cater to the inflation requirements of various Add to Inquiry -

Handhold Automatic Cordless Tire Inflator

AP02 Automatic Cordless Tire Inflator is a wireless intelligent high-pressure inflator that is Add to Inquiry -

Portable Tire Filler

The AP04 car tire inflator is a highly efficient and convenient car inflation tool that utilizes Add to Inquiry -

Car Tire Portable Air Pump

When it comes to inflating your tires, balls, and other inflatables, you want something that is Add to Inquiry -

Smart Air Compressor For Car

AP04 Smart Air Compressor is a truly revolutionary product that provides stable and reliable energy Add to Inquiry -

Car Tyre Pump Battery Operated

Traveling has always been an exciting experience for many people. It is an opportunity to explore Add to Inquiry -

Best Portable Car Inflator

The AP07 is a portable and smart tire inflator designed to meet the quick inflation needs of Add to Inquiry -

Electric Car Tire Inflator

The AP08 Electric Car Tire Inflator is a modern and effective tool for inflating tires on cars and Add to Inquiry -

LED Light Portable Electric Air Compressor

The LED Light Portable Electric Air Compressor is a compact, wireless, and multifunctional tool Add to Inquiry

What is Air Compressor

An air compressor is a mechanical device that increases the pressure of air by reducing its volume. It draws in atmospheric air and then uses one of several methods to compress this air into a smaller volume, thus raising its pressure. The compressed air is then stored in a tank or delivered directly to a system or tool that requires pressurized air for operation.

Air Compressors Are Safe and Convenient

Traditionally, electric-powered tools were used to perform a vast range of domestic and industrial chores. However, we realized that air tools were much more efficient. The air compressor supplies the compacted air to the tools that perform various functions.

Air Compressor Operates Quietly

The air compressor deals with massive airflow, yet works silently. So much so that, you can be in the compressor room and still talk and listen to others. The noise insulation and effective lubrication are the reasons that air compressors are silent. This makes them a suitable tool for indoor use as well as small workshops.

It Increases Productivity

The air compressor improves productivity by dependably supplying clean and stable air to the appropriate pressure. The controls of the air compressor system can be managed to increase its efficiency, which eventually raises production efficiency.

Air Compressor Conserves Energy

Compared to traditional tools, air compressors consume way less electricity. Also, they can be effectively controlled to consume less energy and cut costs.

It Requires Low Maintenance

The best part about air compressors is that they need low upkeep. Unlike electric-powered tools, they don’t have many moving parts that can cause frequent problems. Also, the use of electric-powered tools is limited. For instance, you cannot use them in the presence of water. But there’s no such risk with the air compressor.

Types of Air Compressor

Rotary Screw Compressors

A common type of displacement compressor, rotary screws are some of the easiest types of air compressors to take care of, as they are equipped with an internal cooling system that doesn’t require much maintenance. They are typically large industrial-sized machines that can be either lubricated with oil or run oil-free. Rotary screw air compressors generate energy via two internal rotors that turn in opposite directions. The air gets trapped between the two opposing rotors and builds up pressure within the housing. Because of the internal cooling system, these air compressors are designed for continuous use, and range in power from 5 horsepower up to 350 horsepower.

Reciprocating Compressors

Reciprocating compressors are another popular type of displacement compressor. They are typically found at smaller work sites such as garages and home construction projects. Unlike the rotary screw compressor, the reciprocating compressor is not designed for continuous use. A reciprocating air compressor also has more moving parts, which are lubricated with oil for smoother movement.

Dynamic Compressors

Dynamic air compressors generate horsepower by bringing in air with rapidly rotating blades and restricting it to create pressure. The kinetic energy is then stored as static within the compressor. Axial and centrifugal compressors are the two most common types of dynamic compressors.

Axial Compressors

Axial air compressors are not typically used in construction projects. Instead, they are commonly found in high-speed engines on ships and planes. Axial compressors have a high efficiency rate but are much more expensive than other types of air compressors, making them best suited for aerospace applications requiring high horsepower.

Centrifugal Compressors

Centrifugal air compressors slow and cool incoming air through a diffuser in order to build up potential energy. Because of their multi-phase compression process, centrifugal compressors are able to produce a high amount of energy in a relatively small machine.

Materials of Air Compressor

Cast Iron

Cast iron is commonly used in the cylinders and components that house the pistons in piston compressors. It has excellent wear resistance, good thermal conductivity, and can withstand high compression ratios without deformation.

Aluminum

Aluminum alloy is often used to manufacture compressor parts due to its lightweight properties, thus reducing the overall weight of the compressor. They also have good corrosion resistance and are easier to machine than cast iron.

Stainless Steel

For parts requiring excellent corrosion resistance, stainless steel is used. This is especially true in environments where compressed air contains contaminants that may corrode standard metals.

Steel

High-strength steels are used in parts that are subject to significant stress and wear, such as crankshafts, connecting rods and bearings in piston compressors.

Parts of Air Compressor

Compressor Pump

The pump compresses the air and discharges it Into the receiver. Two-stage air compressors have a minimum of two pump cylinders. By compressing the air twice, first in a larger, low pressure cylinder, then in a smaller, high pressure cylinder, two-stage compressors can produce pressures.

The Piston

As the piston in the pump cylinder moves downward, air enters the large cylinder through the filter and air Intake valves at atmospheric pressure.On the upstroke, the piston in the large cylinder compresses the air to approximately 50 psi, and discharges it to the smaller cylinder through the intercooler tube.

The Receiver

The air is cooled using a flywheel fan this passes through the intercooler and into the smaller cylinder. In the smaller cylinder, high pressure is used to compress further to a final state. As the piston moves upward, it compresses the air and discharges it into the receiver through a check valve.

User EvHow to Choose Air Compressoraluation

Understanding the Different Types Of Air Compressor

Assessing Your Specific Air Compressor Needs

Factors To Consider When Choosing a Air Compressor

How to Maintain Air Compressor

Check the Oil Level

Regularly check oil levels in your compressor’s pump and top it up if necessary. Replace the oil every few hundred hours of operation or according to the manufacturer’s recommendations.

01

Check For Air Leaks

Listen for air leaks, or use a soapy solution to check connections and seals. Repair or replace leaks to prevent your compressor from overworking and losing efficiency.

02

Clean the Air Filters

Regularly clean the inlet air filters to prevent dust and debris from entering the compressor. A clogged filter will reduce airflow and increase the air compressor’s operating temperature.

03

Drain Condensate From Tanks

Water vapor can become a problem in compressed air systems, so it’s essential to drain the condensate that collects in air tanks regularly.

04

Schedule Professional Maintenance

Schedule professional maintenance and inspections with a qualified technician regularly. They can perform thorough checks to identify and fix potential problems before they become costly air compressor repairs.

05

A smart air compressor for car, often referred to as a portable tire inflator, is an electronic device designed to quickly and efficiently inflate a vehicle's tires to the desired pressure using a built-in air compressor. What makes it "smart" is its integration of advanced technology features that enhance usability, accuracy, and convenience.

Features of Smart Air Compressor For Car

Digital Pressure Gauge

A digital pressure gauge is a must-have feature in any car tire air pump, as it provides precise and accurate readings of the tire pressure. This ensures that you can inflate your tires to the recommended levels without over-inflating or under-inflating them, which can lead to uneven wear and reduced fuel efficiency. With a digital display, you can easily monitor the progress of inflation and make adjustments as needed for optimal performance.

LED Light For Nighttime Use

An LED light is an invaluable addition to any car tire air pump, especially when you find yourself needing to inflate a tire in low-light conditions or at night. Whether you're on a dimly lit street or stranded on the side of the road after dark, having an integrated LED light on your tire inflator can provide much-needed illumination and ensure safe and efficient operation.

Automatic Shut-off Function

The automatic shut-off function in a car tire air pump is a game-changer when it comes to convenience and peace of mind. Once you've set your desired tire pressure level, this feature automatically stops the inflation process when that level is reached, preventing over-inflation and eliminating the need for constant monitoring. This not only saves time but also ensures that your tires are inflated accurately every time.

Emergency Functions

Some models include additional safety features like an emergency flashlight, SOS signal, and roadside hazard warning lights to enhance safety during breakdowns or emergencies.

Compatibility With Your Vehicle

Check that the air compressor is suitable for the size of your car's tires. Ensure it can reach the necessary pressure levels for your vehicle's tires and that it comes with the appropriate nozzles for your tire valves.

Pressure Range and Output

Look for a compressor with a pressure range that covers the requirements of your car's tires. The output (CFM or cubic feet per minute) should be sufficient to inflate your tires quickly.

Power Source

Determine how you will power the compressor. Most are powered by a car's 12V cigarette lighter socket, but some more powerful models may require a direct connection to the car battery or an AC outlet. Consider portability and ease of use based on your power source preferences.

Maximum Inflation Pressure

The maximum PSI (pounds per square inch) that the compressor can handle should be higher than your tire's recommended pressure to ensure it can reach the desired level without strain.

Duty Cycle

The duty cycle is the percentage of time the compressor can run continuously before needing a cooling period. A higher duty cycle means the compressor can run for longer periods without overheating.

Build Quality and Durability

Look for a compressor made from high-quality materials that can withstand regular use and the demands of roadside conditions. Check for warranties and customer reviews for insights into durability.

Noise Level

Since you might use the compressor in public areas or at night, consider the noise level of the unit. Some compressors are designed to be quieter than others.

Additional Features

Consider any extra features that could be useful, such as an automatic shut-off to prevent overinflation, a built-in LED light for low-visibility situations, a pressure gauge for monitoring, a carrying case for storage, or an LCD screen for easier reading.

Brand Reputation and Customer Support

Opt for a reputable brand with a history of producing quality products and providing good customer service. This can ensure reliability and access to support if needed.

Price and Value

Set a budget based on your needs and compare prices and features across different models. Remember that the cheapest option might not always provide the best value in terms of performance, durability, and features.

Applications of Smart Air Compressor For Car

Tire Inflation

The primary application is to quickly and accurately inflate car tires to the manufacturer's recommended pressure, which helps maintain safety, fuel efficiency, and tire longevity.

Emergency Situations

In the event of a flat tire or sudden air loss, a smart air compressor can be used to reinflate the tire sufficiently to drive to a repair shop, assuming the tire isn't damaged beyond repair.

Sporting Equipment

Can be used to inflate sports balls, such as basketballs, footballs, or soccer balls, for impromptu games or while on the go.

Inflatable Mattresses

For travelers, a smart air compressor can be used to inflate air mattresses or camping pads, providing a comfortable place to sleep.

Inflatable Rafts and Boats

If you enjoy water activities, a compressor can be used to inflate inflatable rafts, kayaks, or boats.

Bicycle Tires

While not all smart air compressors are designed for bicycles, those with the appropriate fittings can be used to inflate bike tires.

Certificate

Frequently Asked Questions

Q: What is an air compressor?

Q: How does an air compressor work?

Q: What are the main types of air compressors?

Q: What are the common applications of air compressors?

Q: What factors should be considered when choosing an air compressor?

Q: What is the difference between oil-lubricated and oil-free air compressors?

Q: How should an air compressor be maintained?

Q: What is the duty cycle of an air compressor?

Q: Can an air compressor be used for painting?

Q: How can I ensure safety when using an air compressor?

Q: Can an air compressor be used for inflating tires and sports equipment?

Q: What is the role of an air receiver tank?

Q: Are there portable air compressors available?

Q: Can an air compressor be used for cleaning?

Q: Can an air compressor be used for pneumatic tools other than impact wrenches and nail guns?

Q: Are there noise considerations when using an air compressor?

Q: Can an air compressor be used in a home workshop or garage?

Q: Can an air compressor be used for industrial applications?

Q: What is the role of pressure regulators in an air compressor system?

Q: Can air compressors be used in conjunction with other compressed gases?

We're professional air compressor manufacturers and suppliers in China, specialized in providing high quality customized service. We warmly welcome you to buy or wholesale bulk air compressor in stock here from our factory. For price consultation, contact us.

OEM smart tire inflator, Digital Display Cordless Motorcycle Tire Inflator, Portable Motorcycle Air Pump